One example is the Makuace UP-R, a standard-type device for making ultrapure water from tap water.

High-performance reverse osmosis membranes, UV sterilizers, deminars , and UF membranes are also available in a small single package. The Makuace UP-R can be placed near the point of use to save on space and drastically reduce on-site construction.

Ultrapure water production systems

These systems produce water that is nearly theoretically pure water by removing impurities to the maximum. By fully employing various water treatment technologies—including ion exchange, reverse osmosis membranes, electric desalination, and ultrafiltration—we provide systems that are optimally matched to our customers’ needs.

Ultrapure water production systems are largely divided into pretreatment systems, primary pure water production systems ("primary pure water systems"), and polishing systems (subsystems).

Pretreatment systems mainly remove particles from industrial water and well water. Primary pure water systems remove most of the ions, TOCs (total organic carbons dissolved in the water), dissolved gases (oxygen, CO2), and SiO2. Subsystems remove a small quantity of the ions and TOCs that could not be fully removed by the primary pure water system, and also remove the ions and TOCs eluted from system constituting members in and after the process with the primary pure water system.

Kurita combines the latest technologies and devices and offers systems that are optimal for the specific quality of raw water and ultrapure water quality requirements.

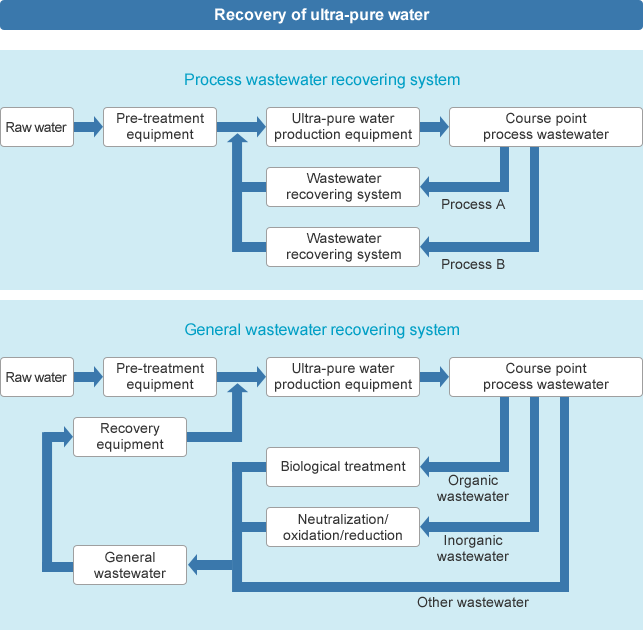

Wastewater reclamation systems

We propose the reclamation and recycling of wastewater with waste reduction also taken into consideration, thus contributing to more effective use of water resources, environmental impact reduction, and cost reduction.

For example, Kurita provides semiconductor plants with a system for collecting some of the ultrapure water used in the different production processes and reusing it to make ultrapure water. Wastewater may be collected separately for each production process, or as general wastewater mixing organic wastewater with inorganic wastewater after partial treatment. Kurita engineers an optimal meeting point for the primary system by controlling the quality of water for collection and the quality of water that has been collected and treated.

Wastewater treatment systems

The characteristics of wastewater discharged from factories vary from industry to industry. Kurita therefore provides systems that employ a broad range of technologies to reliably treat industrial wastewater in various forms and conditions.

These systems include biological treatment systems for decomposing organic substances in wastewater with the use of microorganisms, and pressurized floatation systems for removing suspended substances and other substances by using the difference between water and these substances in specific gravity. In addition to these systems, Kurita offers optimal wastewater treatment devices such as sedimentation treatment systems and belt-presses, screw-presses, polydiscs, and many other types of dehydrators by employing its abundant know-how on water treatment and adapting these devices to the wastewater properties, water volume, required level of water treatment quality, and other specific characteristics.

Water treatment facilities for various industries

We provide facilities for manufacturing water that meet various industrial needs, including water for pharmaceutical use, such as injectable drugs and eye medications, water for manufacturing foods and beverages, and boiler water for use in the electric power and steel industries. We also provide amenity related facilities such as water slides.

One example is the purified water used as a raw material for pharmaceutical drugs and for cleaning drug manufacturing devices. This purified water is prepared with the use of a system that combines ion exchange, membrane filtration, and other technologies to remove ion components and impurities from raw water. Ensuring a consistent level of quality in this water requires the proper management of living bacteria. Kurita performs sterilization with water that is 80 degrees Celsius or warmer, combines ultraviolet sterilization practices, and is capable of offering purified water production systems that are very effective in inhibiting the proliferation of living bacteria and improving the quality of water for pharmaceutical use.

For more than three decades, Kurita has provided pharmaceutical industries with numerous systems for the production of purified water, sterile purified water, and the injection of solvents. Today it commands the top share in Japan.

Standard-type water treatment equipment and standard-type wastewater treatment equipment

Standard-type water treatment equipment

Kurita has a substantial lineup of small- and medium-sized water treatment equipment, with standardized specifications and drawings related to the volume of treated water and other features.

The set of devices necessary to operate the equipment—such as the water treatment unit with the resin, membrane, and other substances; pumps, plumbing, and control panels—is assembled on a stand within the premises of a plant, and completes trial operation before it is shipped. After installation, the equipment can immediately start operation, helping to reduce costs as well as shorten the design and construction periods.

We have an extensive lineup of pretreatment devices, filtration devices, deionizers, and wastewater treatment devices. We can also combine our standard products to satisfy customer requests for water volume and quality.

In addition, our products can be used in ultrapure water production systems that require a high purity of water.

Standard-type wastewater treatment equipment

In the past, the water tanks that served as aeration tanks for biological treatment and other purposes were often made of concrete. However, the steep rise in construction labor costs and material costs combined with the shortage of skilled workers in recent years is making it harder to build the concrete water tanks that need to be constructed on a grand scale.

To solve these problems, Kurita developed standard-type wastewater treatment equipment to drastically simplify construction work. Replacing the conventional concrete tanks, this is a groundbreaking biological treatment system that employs an FRP tower tank that stands 10 meters. It involves simple on-site construction and civil engineering, and compared to conventional wastewater treatment equipment, it greatly shortens the period from the start of construction to the completion of trial operation. Our standard-type wastewater treatment equipment also helps reduce introduction costs by 40% and installation space by 20%.