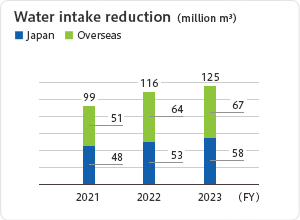

The graph shows the performance of water reduction at customers’ plants and business sites through proposals of the Kurita Group. These mainly represent reduction in the feed water volume by optimizing and managing water quality in boilers and recirculating water in cooling water systems, as well as recovery and reuse of wastewater.

The Kurita Group Approach

The world is facing various issues related to water, including water shortages due to uneven distribution, water pollution associated with industrial development, and depletion of ground water. These rank among the most serious social issues alongside climate change. The Kurita Group will strive to reduce the amount of water intake for use in its business activities while using its water savings, purification, and reuse technologies to provide the optimal quality and volume of water required for people’s lives and industrial development.

Contribution to Achieving the SDGs

Targets and Achievements

The Kurita Group aims to achieve a reduction of environmental impact through its business that offsets and even exceeds the environmental impact generated by its business. To this end, we have set targets for the “Water savings at customers – Amount of water intake used in our business activities.” We will continue to measure these actual values going forward.

| Target for FY2023 | Achievement in FY2023 | |

|---|---|---|

| Water savings at customers – Amount of water intake used in our business activities | 240 million m³ | 122 million m³ |

With Customers

Saving Water at Customers’ Plants and Business Sites

Environmental Improvement of

Customers’ Operations

Customer Example

Shanghai Kao Chemical Co., Ltd.: Environmental Improvement Case Study

(Project

by Kurita Water Industries (Dalian) Co., Ltd.)

Shanghai Kao Chemical Co., Ltd. produces surfactants used as raw material in

various products such as industrial detergents and cosmetics, as well as

casting-related materials. As a member of the Kao Group, Shanghai Kao

Chemical is working to reduce its environmental impact in accordance with

the Kao Group’s basic philosophy and basic policy on environment and safety.

The Kao Group aims to reduce water consumption across the entire lifecycle

of its products, and as a production plan, Shanghai Kao Chemical is

continuously promoting efforts to reduce the amount of water used in

production.

Kurita Water Industries (Dalian) Co., Ltd. examined a range

of water saving measures with the customer to help tackle the challenge of

reducing water consumption. Focusing mainly on reducing industrial water for

cooling, which accounts for around 40% of water consumption, we came up with

a water saving strategy of recovering the blow-down water from a cooling

tower, which was previously treated as wastewater, as well as rainwater and

wastewater from a boiler, treating it with a membrane process to reach the

standard quality required for cooling water, and then reusing it as

supplementary cooling water supply. The introduction of this strategy

enabled a reduction of around 70% in the customers industrial water for

cooling.

Voice of the Customer

Fan Yiming

General Manager, Production Department

Kao (Shanghai) Chemical Industries Co., Ltd.

Kurita is a water treatment specialist and its corporate philosophy is in concord with the Kao Group’s vision of “Sustainability as the only path,” expressed in its medium-term management plan, as well as the core tenet of Kao’s ESG strategy, “Yoki-Monozukuri with ESG integration.” Our newly installed Cooling Tower Blow-down Recovery system is compact and offers a stable treatment flow, as well as a high degree of automation and intelligent operation coupled with a high recycled water recovery rate. The introduction of this system has reduced the volume of industrial water used for cooling by around 70%, which translates into an overall reduction of around 40% in both the total annual usage of industrial water and the total wastewater volume for the entire plant. We have also requested ongoing support and maintenance services.

This website uses the names of products and services in Japan. Please note that product and service names differ in other countries.

Internal Environmental Improvement Activities

Reducing Water Intake within the Kurita Group

Internal Promotion of Environmental

Improvements

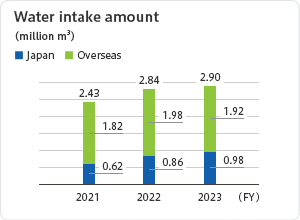

Based on the characteristics of each company and business site, the Kurita Group selects the items that are strongly correlated with water usage, such as production volume, net sales, or site area, as the denominators for a per-unit measurement, then set about reducing water usage per unit.

P.T. Kurita Indonesia: Water Savings Case Study

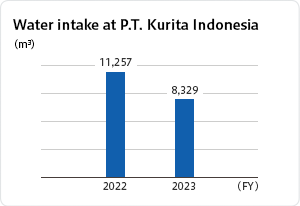

Water intake at P.T. Kurita Indonesia

P.T. Kurita Indonesia’s business operations involve the manufacture and sale of water treatment chemicals and equipment, as well as the operation, maintenance, and management of water treatment facilities. The company is taking steps to reduce water consumption by using concentrated water discharged from RO membrane equipment, which is part of a pure water production system for products, to wash used raw material packaging and so forth. RO membrane equipment separates water into concentrated water and permeate water by passing feed water through a membrane to remove the salts in it. The concentrated water has a higher salt concentration than the feed water, but it can readily be used for washing. Using this measure, P.T. Kurita Indonesia has reduced its water intake by 26% year on year.

Evaluation of Water Risk at Internal Sites

Kurita assesses and ascertains water risk for each Group site using the World Resources Institute's Aqueduct Water Risk Atlas as well as benchmarks such as the ratio of water intake of each facility to the total water intake of the Kurita Group, business characteristics, and other criteria. Based on the assessment results, the E&S Committee, which oversees the Kurita Group’s environmental improvement activities, has identified 25* facilities as priority sites for water risk mitigation and is pursuing efforts to mitigate risks.

- * As of March 2023

Participation in Water Resilience Coalition

Kurita is a Leadership Committee member of the Water Resilience Coalition (WRC).

The WRC is a new organization established under the CEO Water Mandate, a United

Nations Global Compact initiative. It leads industry-driven initiatives for the

preservation of water resources in basins facing serious water resource problems

all over the world. As a member of the WRC, the Kurita Group will work to preserve

the world’s water resources together with other companies and organizations,

aiming to achieve the Sustainable Development Goals (SDGs) and its Corporate

Philosophy.

The Company has also participated in the UN Global Compact and endorsed the CEO

Water Mandate.

| Target fiscal year | Kurita Group targets |

|---|---|

| FY 2031 | Total number of basins where collective actions are implemented and total population in the basins: 7 basins, 700 million people |

Please refer to the links below for more details about the Kurita Group’s initiatives through the WRC. The link includes the latest information for FY2024 onward.

Participation in the Ministry of the Environment’s Water Project

Kurita Water Industries is participating in the Water Project of Japan’s

Ministry of the Environment, which provides an opportunity to disseminate

information about its technologies and business activities related to efficient

use of water resources and preservation of the water environment.

Details

of the Water Project are

here. (In Japanese only)