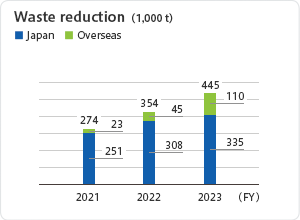

The graph shows the performance of waste reduction at customers’ plants and business sites by means of proposals of the Kurita Group. These results are mainly due to conversion to wastewater treatment facilities that generate little excess sludge and reduction of waste volume by dehydrating agents and dehydrators.

The Kurita Group Approach

The Kurita Group needs to make effective use of limited resources in order to

conduct its business activities sustainably. Therefore, the Group is working to

reduce the amount of waste (including hazardous or toxic waste) generated by its

business activities, while making efforts to convert it into valuable material and

to recycle it.

For our customers, we propose technologies for making use of

waste as a resource and for reducing the amount of waste generated. Through these

activities, we aim to reduce waste for society in general.

Contribution to Achieving the SDGs

Targets and Achievements

The Kurita Group aims to achieve a reduction of environmental impact through its business that offsets and even exceeds the environmental impact generated by its business. To this end, we have set targets for the “Waste* reduction at customers – Waste* generated from our business activities.” We will continue to measure these actual values going forward values.

| Target for FY2023 | Achievement in FY2023 | |

|---|---|---|

|

Waste* reduction at customers – Waste* generated from our business activities |

450,000 t | 406,000 t |

* including hazardous or toxic waste

With Customers

Waste Reduction at Customers’ Plants and Business Sites

Environmental Improvement of

Customers’ Operations

Customer Example

Die Cast Products Plant: Environmental Improvement Case Study

(Project by Kurita Water Industries (Dalian) Co., Ltd.)

A customer that manufactures processed aluminum products in China is working

to reduce its environmental impact at every stage of the product lifecycle in

accordance with its environmental policy. Among these environmental impacts,

the customer is continuously working to reduce industrial waste and increase

recycling by thoroughly implementing waste separation.

Kurita Water

Industries (Dalian) Co., Ltd. proposed a approach for reducing industrial

waste by lowering the amount of water treatment chemicals used in a wastewater

treatment facility to reduce waste originating from the reaction of water

treatment chemicals and impurities in the wastewater. The wastewater treatment

facility uses a range of water treatment chemicals such as flocculants to

render wastewater non-hazardous. The treatment status of the wastewater is

constantly monitored by sensors and the quantity of chemical additives used

for its treatment and stabilization is optimized by automatic control to

enable waste to be reduced. By adopting this proposal, the customers waste was

reduced to around one tenth of the previous amount. Furthermore, the reduction

in waste also enabled a reduction in the frequency of operation of dehydration

equipment, while automatic control enabled stabilization of the wastewater

treatment and power saving.

This website uses the names of products and services in Japan. Please note that product and service names differ in other countries.

Internal Environmental Improvement Activities

Reduction of Internal Waste

Internal Promotion of Environmental

Improvements

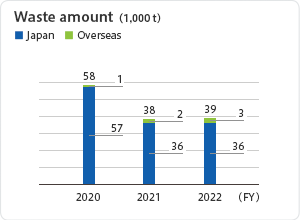

Based on the characteristics of each company and business site, the Kurita Group selects the items that are strongly correlated with waste emission volume, such as production volume, net sales, or site area, as the denominators for a per-unit measurement of waste emission volume, then set about reducing this. The Group has been aggregating the total volume of waste at construction sites of the Company and domestic group companies since fiscal 2020.