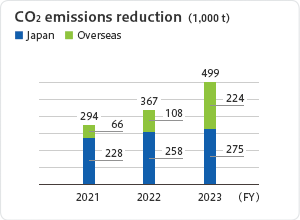

The graph shows the performance of CO2 emissions reduction at customers’ plants and business sites through proposals of the Kurita Group. These mainly represent reduction in fuel use by maintaining or improving heat efficiency in boiler and cooling water facilities. It also represents the impact of adopting inverters for rotating equipment in water treatment facilities.

The Kurita Group Approach

The Kurita Group recognizes abnormal weather and natural disasters due to global warming and other climate change issues as a major social challenge to be addressed globally. One of the ways we are responding to climate change is taking steps to reduce our CO2 emissions by reducing our in-house per-unit energy consumption. At the same time, we are working to optimize energy use at our customers’ plants and business sites, and to promote the spread of energy-creating technologies.

Contribution to Achieving the SDGs

Targets and Achievements

The Kurita Group aims to achieve a reduction of environmental impact through its business that offsets and even exceeds the environmental impact generated by its business. To this end, we have set targets for the “CO2 emissions reduction at customers – CO2 emissions from our business activities.” We will continue to measure these actual values going forward.

| Target for FY2023 | Achievement in FY2023 | |

|---|---|---|

|

CO2 emissions reduction at customers*1 – CO2 emissions from our business activities*2 |

10,000 t | 249,000 t |

- *1 Please refer to the link below for the details of “CO2 emissions reduction at customers.”

Environmental Improvement of Customer's Operations

- *2 “CO2 emissions from our business activities” includes emissions generated from ultrapure water supply business which applies to Category 13 of Scope 3 adding to the Scope 1 and 2 stipulated in GHG (Greenhouse Gas) protocol.

To carry out initiatives in line with the Paris Agreement, the Kurita group has set the long-term targets aligned with the well below 2℃ indicated by SBTi*3, starting from the fiscal year ended March 31, 2020 as the baseline year, and are working to reduce Scope 1, 2, and Scope 3 emissions in addition to the above-mentioned targets.

Initiatives to Address Climate Change

| Metrics | Long-Term Targets | |

|---|---|---|

| FY2031 | FY2051 | |

|

Scope 1 and 2 emissions reduction (Reduction rate from FY2020) |

27.5% | 100% |

|

Scope 3 emissions reduction (Reduction rate from FY2020) |

27.5% | - |

- *3 An initiative that encourages companies to set greenhouse gas emission reduction targets in line with scientific knowledge, with the goal of limiting global average temperature rises due to climate change to well-below 2℃ compared to pre-industrial levels.

With Customers

Reducing CO2 Emissions at Customers’ Plants and Business Sites

Environmental Improvement of

Customers’ Operations

Customer Example

Cardboard Manufacturing Plant: Environmental Improvement Case Study

(Project by Kurita Kitakantou Co., Ltd.)

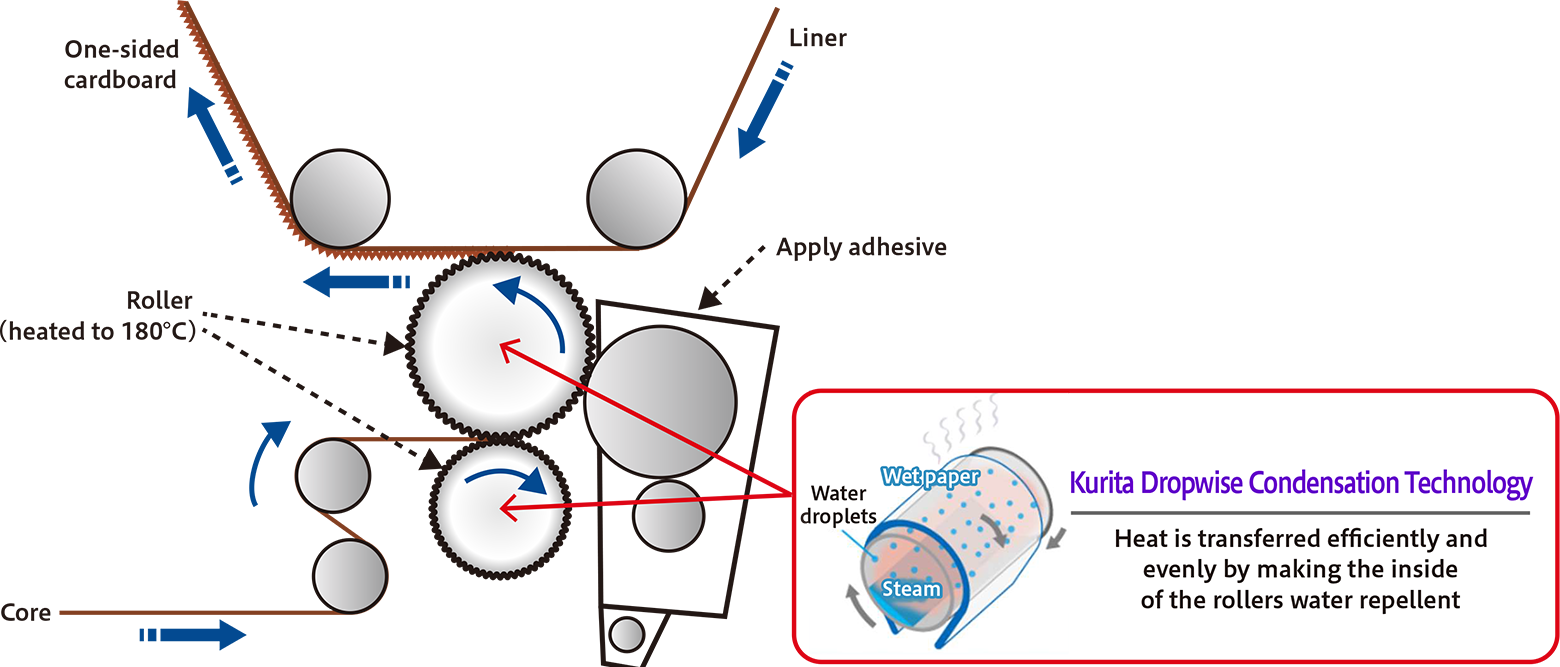

Corrugator units for manufacturing cardboard sheet are generally used at plants

that manufacture cardboard products. These units press carboard feedstock paper

between metal rollers to produce a corrugated core, then adhere front and back

liner sheets onto the core surface. To firmly fix the core to the liners with

adhesive, it is heated by passing steam through the inside of the rollers. The

challenge for reducing CO2 emissions at cardboard manufacturing is

therefore to reduce the amount of fuel used in the boilers that supply the

steam.

Kurita Kitakantou Co., Ltd. proposed to its cardboard manufacturing

plant customer the application of a technology to improve the thermal

conductivity of the rollers by making the interior metal surface water

repellent. When the steam condenses on the metal surface upon contacting it, a

water film forms. Despite being very thin, this film can significantly reduce

thermal conductivity, which causes more energy to be needed for stabilizing the

heating temperature. The technology proposed by Kurita Kitakantou removes this

water film. Applying this technology helped the customer to reduce their boiler

fuel consumption by around 6%, and by applying the same technology at other

plants, further fuel savings were achieved.

Process for adhering core and liners in a corrugator

This website uses the names of products and services in Japan. Please note that product and service names differ in other countries.

Internal Environmental Improvement Activities

Reducing Energy Usage within the Kurita Group

Internal Promotion of Environmental

Improvements

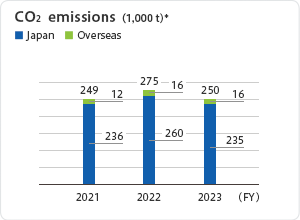

Based on the characteristics of each company and business site, the Kurita Group selects the items that are strongly correlated energy usage, such as production volume, net sales, or site area, as the denominators for a per-unit measurement, then set about 1% reduction of energy usage per unit year on year.

Kurita Group KPI: Customer Impact Reduction – Kurita Group Impact

Promotion of EVs and Renewable Energy Transition

In fiscal 2023, the Kurita Group took steps to reduce in-house energy usage, such as switching its vehicle fleet from gasoline to electric vehicles and promoting a transition to renewable energy at bases that have a high volume of CO2 emissions from electric power use. These resulted in a 9% decrease in CO2 emissions from the previous fiscal year. In addition, the Group’s R&D base, Kurita Innovation Hub, which started operations in fiscal 2023 also uses 100% renewable energy.

The Kurita Group Accelerates the Actions on Climate Change Based on TCFD Recommendations*

The Kurita Group views climate change as an urgent issue that needs to be

addressed globally, and continuously reduce greenhouse gases generated by our

business activities and contribute to reducing greenhouse gas emissions for our

customers through our business. In order to realize the Kurita Group’s sustainable

growth going forward, we analyzed the risks and opportunities of climate change

and its impact on our business strategies at E&S (Environmental and Social)

Committee, and set medium- to long-term targets and measures for the reduction of

greenhouse gas emissions based on the TCFD Recommendations.

In addition, we

established a system which the Board of Directors oversees the actions on climate

change issues. Please refer to “The Kurita Group’s Initiatives Addressing Climate

Change” in detail.

-

* Final Report: Recommendations of the Task Force on Climate-related Financial

Disclosures (TCFD) (June 2017)

Please refer to the link for the latest information for fiscal 2024 onward.

Participation in METI’s GX League

The Company participates in the GX League. The GX League was organized by

Japan’s Ministry of Economy, Trade and Industry (METI) to realize the

Japanese government’s target of “carbon neutral by 2050.” Specifically, the

GX League will provides a forum for discussion on transformation of the

socioeconomic system through collaboration between companies actively

engaging in GX* and entities in government, academia, and

finance, as well as practical implementation for the creation of new

markets.

Based on the Recommendations of the Task Force on

Climate-related Financial Disclosures (TCFD), the Kurita Group continues to

work to reduce GHG emissions generated by its own business activities, as

well as to reduce GHG emissions for customers through its businesses. We are

committed to helping to realize a decarbonized society through participation

in the GX League.

-

* Green transformation

Click here for details on the GX League.

Participation in the Japan Business Federations' Challenge Zero program

Kurita is taking part in Challenge Zero, an initiative run by Keidanren (Japan Business Federation) to develop innovative net zero greenhouse gas emission technologies. As of August 2023, 195 companies and groups had signed up to the initiative, aiming to rapidly achieve the net zero greenhouse gas emissions targets in the Paris Agreement.

Participation in the Japan Society of Industrial Machinery Manufacturers’ Basic Environmental Action Plan

Kurita Water Industries participates in the basic environmental action plan of the Japan Society of Industrial Machinery Manufacturers, which is working on countermeasures for global warming. We report regularly on the status of our response to climate change.