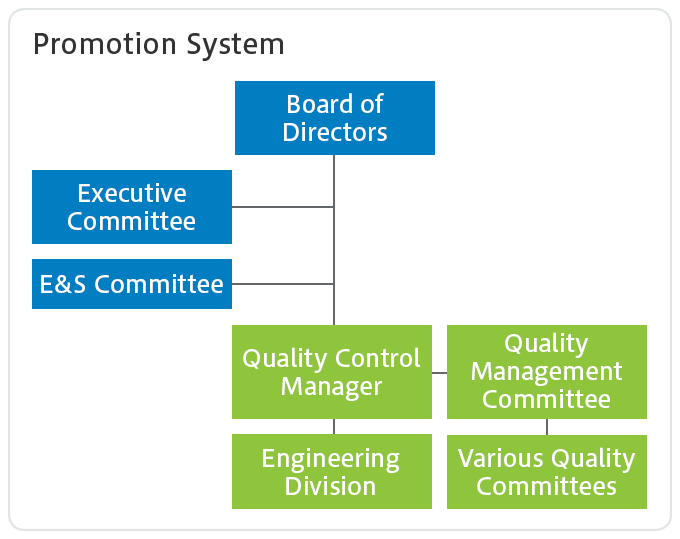

The Kurita Group has established a quality management system that includes the quality management divisions of Group companies, the Company’s Quality Management Committee, and other quality management committees, including those at Group companies. The Quality Control Manager oversees these committees, and determines and assesses quality outcome goals and progress toward process goals, reporting the results to the Board of Directors once a year.

Improving Quality

In order for the Kurita Group to continue its business and grow as a company, it

must maintain its status as a trusted supplier for its customers. To gain the trust

of our customers, we believe we must consider the impact on customers of the actual

products and services that we supply, which is to say, we must develop products and

services that consider safety, health, and environmental impact throughout the

product lifecycle, and also ensure their stable manufacture as well as safe shipment

and delivery.

The Kurita Group will strive to maintain the trust of society by continuing to

develop and provide products and services that are considerate of safety, health,

and the environment.

Contribution to Achieving the SDGs

Basic Policy

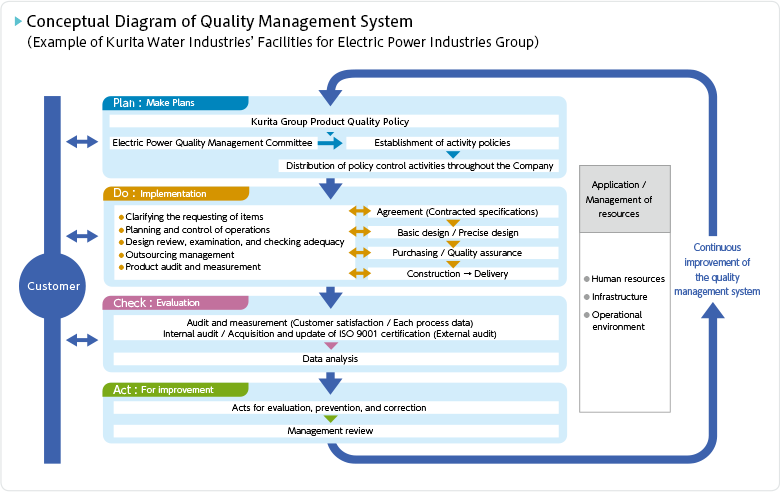

The Kurita Group has established the “Kurita Group Product Quality Policy” and

continuously promotes quality improvement activities based on this policy in an

effort to raise the quality of the products and services it provides to

customers.

The basis of this policy is the “Kurita Group will speedily provide

our customers with products and services that can meet their quality expectations,

thereby winning unshakable trust.” To provide products and services that are trusted

by customers and to fulfill our social responsibilities in conducting our business,

we have established the policy with the goal of conducting quality activities that

take into account observance of laws and regulations, safety and quality, and

environmental impact.

To improve quality, each Group company has built and

operates a quality management system based on the policy. In addition, we constantly

monitor the current quality level through self-inspections, surveys by the person in

charge of promoting quality improvement activities or their designated person, and

feedback of opinions and requirements from customers. Improvements are made each

time an issue is recognized.

Kurita Group Product Quality Policy (FY2023)

Kurita Group Product Quality Policy

- We will establish a quality management system suitable for the business environment and continue improvement activities to enhance customer satisfaction.

- We will actively disclose appropriate information concerning products and services and provide safe and secure products and services.

- We will determine quality control processes and criteria, properly operate them, regularly confirm the operation status and thereby secure the quality of products and services.

- We will promote the development and improvement of products and services considering environmental impact and contribute to environmental preservation.

Targets and Achievements

The Kurita Group’s targets and achievements for the fiscal 2023 for the theme are as shown below.

| Targets for FY2023 | Achievements in FY2023 | |

|---|---|---|

| Rate of safety evaluations for newly developed products | 100% | 100% |

| Rate of front-line employee participation in regular safety training directly related to products and services | 100% | 100% |

Main Initiatives

Safety Evaluation of Newly Developed Products

The Company has a rule that, when it uses a new chemical substance in product development, it assesses the risk the chemical substance poses to the environment and health based on internal rules. In addition, when we manufacture a product, we submit mandatory notifications and reports following laws and regulations, including the Industrial Safety and Health Act, the Act on the Evaluation of Chemical Substances and Regulation of Their Manufacture, etc., and the Fire Service Act.

Sharing Information Related to Product Safety

To ensure the appropriate provision of information to customers, Kurita Water Industries uses GHS*1-compliant SDS*2 and labels to inform them of applicable laws and hazards of the product and provide other information. We also issue Yellow Cards*3 and affix Yellow Card-compliant labels to containers*4 to ensure transportation safety.

- *1 GHS stands for the Globally Harmonized System of Classification and Labeling of Chemicals. Under this system, physical hazards and health hazards/environmental hazards of chemicals are classified based on international standards, and products classified as hazardous ones are stated on SDSs and indicated on the containers. GHS has been introduced in many countries in accordance with a recommendation by the United Nations. In Japan, compliance with GHS is required by the Industrial Safety and Health Act.

- *2 SDS (Safety Data Sheet), is a sheet on which a product’s hazards, applicable laws, how to handle and transport the product, emergency measures, and other information are presented in a specific format. The Company creates SDSs for all of its products, commodities, and developed articles and provides them to its customers.

- *3 A Yellow Card is a yellow-colored card showing information about procedures for handling an accident as a safety measure for transportation of a chemical. This card is taken along by the transport operator when a chemical is transported on a tanker truck or the similar vehicle.

- *4 A Yellow Card cannot be used in the case of consolidated transport or transport of small lot products. Therefore, in such a case, the Company affixes a label indicating safety information (United Nations Number and Emergency Response Guide Number of the chemical name) on each container.

Clarifying Customer Evaluations with NPS℠ Surveys

The Kurita Group conducts an NPS℠ survey and utilizes the findings for creating sales and marketing strategy and transforming business processes. In fiscal 2022, the survey was administered to customers in Japan and overseas, and responses were obtained from 929 companies and 1,477 individuals. The next survey will be held in fiscal 2024.

* NPS℠ is the registered trademark or service mark of Bain & Company, Fred Reichheld, and Satmetrix Systems.

Providing Training to Improve Knowledge and Skills

In order to raise the quality of services provided to customers, the Company runs training courses to improve the expertise and skills of all Kurita Group employees. The courses comprise units on a range of topics, including basic knowledge about water treatment chemicals, technical training about water and wastewater treatment, safety and legal training, communication skills and problem-solving.

Technical training session

| Number of Participants in Training (Fiscal Year Totals) | |

|---|---|

| FY2021 | 1,906 |

| FY2022 | 3,042 |

| FY2023 | 2,382 |

Safety Training

The Company runs a product safety e-learning course for Kurita Group employees. The course is designed to deepen employee understanding about product safety.

| Number of Participants | FY2021 | FY2022 | FY2023 |

|---|---|---|---|

| Kurita Water Industries, Group companies in Japan | 5,789 | 3,236 | 3,281 |

| Group companies overseas | 2,454 | 2,394 | 2,525 |

| Total | 8,243 | 5,630 | 5,806 |

Response to Defects

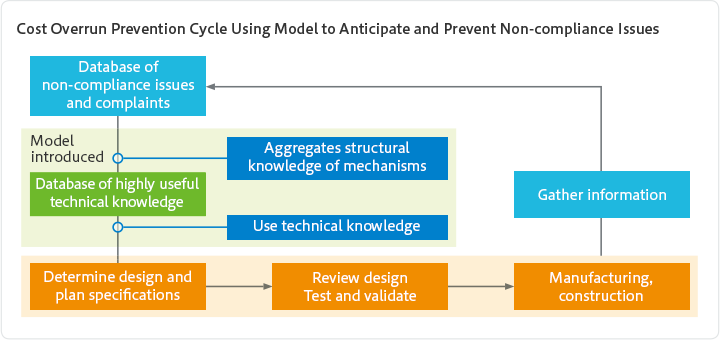

Defects that arise prior to installation at customers and complaints received from customers are entered in the in-house “problem information” database and that information is shared widely throughout the Company.

Internal Audit

In fiscal 2023, we reviewed the quality-related internal audit framework and quality-related education and training that we have implemented so far. Our aim in doing so is to enable each organization to improve the quality management system autonomously. We will continue using the quality committees of each organization to conduct internal audits, working to improve quality by understanding the issues and addressing them with improvements.

Quality Survey Conducted by External Institution

Since fiscal 2021, the Company has engaged an external institution to conduct quality surveys, covering Group companies in Japan involved in production. The surveys cover the quality management systems and operation status of each company. Based on the survey’s findings, quality-related issues were identified and improvement measures formulated as we continue to raise quality levels at domestic Group companies.

Using Change Point Management to prevent abnormalities

As a quality improvement initiative, in fiscal 2023 we have focused on Change Point Management. For work that falls under the 3H of hajimete / henko / hisashiburi (“first time / change / after a long time”), where the probability of occurrence of abnormalities and malfunctions is high, we examine the problem in advance and devise a way of addressing it. We will continue this initiative, preparing to prevent mistakes and to quickly address changes when they arise.

Introducing SSM to Shift from Recurrence Prevention to Simple Prevention

To improve the quality of product design, Kurita became the first engineering company in Japan to introduce a Stress-Strength Model (SSM)* to prevent defects and stop issues from reoccurring. Building and leveraging the SSM framework will help curb the occurrence of defects. Since fiscal 2021, we are also using SSM in the project order approval process, as well as in the design process. We plan to extend the use of SSM to Group companies in Japan and overseas as well to strengthen product quality management across the Group.

- * A mechanism for structurally identifying and rendering into shareable knowledge the mechanisms of defects, to be used to prevent defects and stop issues from reoccurring. A quality management approach mainly used in the manufacturing sector, developed by Yasuhiko Tamura of the Institute of Structured Knowledge Yielding Co., Ltd.

| Number of Serious Accidents in the Kurita Group Involving Products and Services | |

|---|---|

| FY2021 | 0 |

| FY2022 | 0 |

| FY2023 | 0 |

Acquisition of ISO 9001 Certification

To encourage continuous quality improvements, the Kurita Group is promoting

acquisition of ISO 9001 certification at companies that have production processes

involving procurement, manufacture, and processing to provide products and services.

The results of the periodic review conducted by the assessment body at the company

acquiring certification are shared with the Company’s Quality Control Department,

and we assess how to address any issues.

The status of certifications acquired

as of March 2023 is as follows. For data such as overall acquisition rate for the

entire Group, refer to presented under ESG Data-Social.

List of ISO 9001 Certified Bases (As of March 2023)

-

Kurita Water Industries Ltd.

(Facilities for Electric Power Industries Group,

Sales and Engineering for

Chemical Cleaning of Power Station Boilers)*1 - Kurita Chemical Manufacturing Ltd.

- Kurita Analysis Service Co. Ltd.

- Kurita Meiki Ltd.

- Kuritec Service Co. Ltd.*2

- Kuritaz Co., Ltd.

- Kurita Creation Co., Ltd.

- Land Solution Inc.

(Environmental Management Department Ⅲ) - Kurita-GK Chemical Co., Ltd.

- Kurita (Taiwan) Co., Ltd.

- Kurita Water Industries (Dalian) Co., Ltd.

- Kurita Water Industries (Jiangyin) Co., Ltd.

- Hansu Co., Ltd.

- Kurita Europe GmbH (Ludwigshafen)

- Kurita France S.A.S.

- Kurita Italia S.r.l.

- Kurita Iberica SL

- Kurita Turkey Kimya A.S.

- Kurita AquaChemie Saudi Arabia Co.

- Kurita AquaChemie FZE

- Kurita UK Ltd.

- Keytech Water Management

- Kurita do Brasil LTDA.

- Kurita Water Industries (Suzhou) Ltd.

- Hansu Technical Service Ltd.

- Kurita (Singapore) Pte. Ltd.

- Kurita Water (Malaysia) Sdn. Bhd.

- PT Kurita Indonesia

- Kurita America Inc.

*1 Includes Miyoshi Industries Co., Ltd.

*2 Includes San-ei Industries Co., Ltd., Nippon Fine Co., Ltd., and Aoi Industries

Co., Ltd.

CSR Requirements for Suppliers

The Kurita Group considers it vital to obtain cooperation from suppliers to provide

customers with safe, high quality products and services. To this end, we have

established the Kurita Group CSR Procurement Guidelines, and we have asked suppliers

to comply with laws and regulations regarding product safety, provide high quality

products and services to the Kurita Group, and provide appropriate information. In

particular, we ask major suppliers to conduct a self-evaluation based on the

guideline and to implement improvement measures.

In addition, since fiscal

2022, we have been using the platform* of EcoVadis for the purpose of

expanding evaluation items, enhancing the reliability of evaluation results, and

reducing the burden on suppliers. As of March 2023, 123 suppliers in Japan and

overseas (accounting for 28% of total order amount in fiscal 2021) were registered

on the platform.

- * A platform for rating the sustainable procurement capabilities of suppliers from a CSR perspective. The content and number of questions are customized according to industry, company size, and country or region.