2020

January 17, 2020

Kurita Water Industries Wins Agency of Natural Resources and Energy Director-General's Award in the 2019 Energy Conservation Grand Prize for Improved Heat Transfer Efficiency through Dropwise Condensation Technology

Kurita Water Industries Ltd. (Head Office: Nakano-ku, Tokyo; President: Michiya Kadota; hereinafter "Kurita") is pleased to announce that it has been awarded the Agency of Natural Resources and Energy Director-General's Award in the Product and Business Model category of the 2019 Energy Conservation Grand Prize organized by The Energy Conservation Center, Japan (backed by the Ministry of Economy, Trade and Industry). The prize was awarded for the improved heat transfer efficiency through Kurita's Dropwise Condensation Technology. This marks the second time Kurita has been recognized in the Energy Conservation Grand Prize, after winning the Energy Conservation Center Chairman's Award for its DReeM Polymer™ technology in 2017.

The Energy Conservation Grand Prize recognizes exemplary energy conservation initiatives on the part of business operators and sites, as well as products and business models that demonstrate excellent energy conservation. The endeavor is or ganized to expand awareness of energy conservation in Japan, encourage the widespread adoption of energy-saving products, and help build an energy conservation-oriented society. In the 2019 Energy Conservation Grand Prize a total of 52 themes were identified for recognition, with the Agency of Natural Resources and Energy Director-General's Award in the Product and Business Model category going to five recipients.

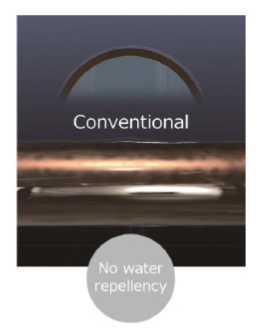

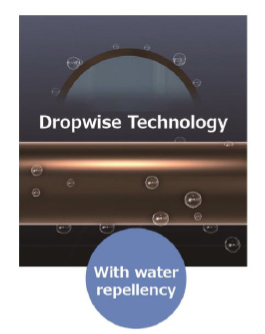

Under the award-winning theme, Kurita was recognized f or its efforts to achieve energy conservation through its new Dropwise Condensation Technology and for the underlying technology. In general, a layer of water forms on the metal surfaces at the steam end of heat exchangers that use steam generated by boilers, due to condensation of the steam. While extremely thin, this layer of water drastically reduces heat transfer efficiency, resulting in higher energy consumption and lower productivity due to the higher amount of steam that needs to be used. Kurita's Dropwise Condensation Technology gives water repellent properties to the metal surfaces of heat exchangers to remove the layer of water and improve heat transfer efficiency. This in turn conserves energy thanks to the reduced amount of steam used, and boosts productivity. Moreover, since the effect is produced by simply adding a water treatment chemical with water-repellent properties to the steam line immediately before a heat exchanger, the solution can be adopted with production facilities still operating.

Kurita is currently rolling out solutions using this technology across various fields of business, and has verified its effects at a paper mill, where per-unit steam consumption and CO2 emissions have been reduced by 5-10% per year on average. The energy co nservation effects can be further enhanced with control in combination with IT and sensing technologies. Moving forward, Kurita rolls out these solutions as a contract-based business where it shares benefits for production equipment such as reduced energy usage and higher production volume with customers.

Under the MVP-22 Medium-term Management Plan, Kurita sees "solving issues related to water resources" and "realizing sustainable energy use" as social issues to be tackled on a priority basis, and is focused on creating shared value with society. With close attention being paid to how energy usage can be optimized in industry, the Kurita Group aims to deliver plant-wide thermal efficiency improvements, and will continue to work with customers in pursuit of sustainable energy usage.

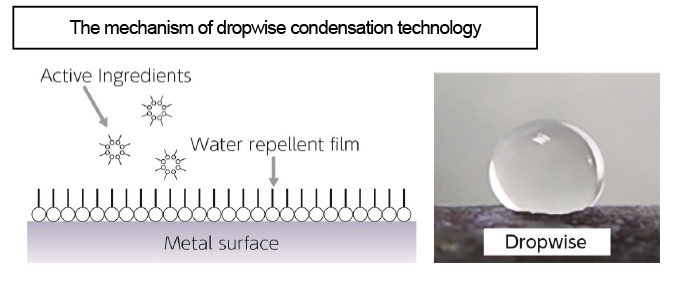

Overview of Dropwise Condensation Technology

An ingredient in the chemical with water repelling properties adheres to the metal surface and transforms the condensation state of the water from a film to droplets.

As the layer of water causing heat resistance is removed, heat transfer efficiency is improved.

A layer of water forms on the metal surfaces of heat exchangers and becomes an obstacle to heat exchange.

By giving the metal surfaces water repelling properties, the condensed state of steam is changed from a film to droplets, which improves heat transfer efficiency.

Energy Conservation Grand Prize Award Ceremony, Exhibition and Explanatory Session

The award ceremony for the 2019 Energy Conservation Grand Prize will take place at the ENEX2020 44th Energy and Environment Exhibition held on Wednesday, January 29 at Tokyo Big Sight. An explanatory session on Kurita's Dropwise Condensation Technology (presentation by the award winner) and panel displays will also be at the same venue.

Dropwise Condensation Technology introductory page

February 1, 2018 press release on the Energy Conservation Grand Prize for DReeM Polymer™