2022

September 27, 2022

Kurita Water Industries and Hitachi Launch DX Co-creation for Managing Steel Mill Raw Material Yards

Will visualize moisture risks and push development of solutions contributing to higher productivity and lower environmental impact

Kurita Water Industries Ltd. (Head office: Nakano-ku, Tokyo; President: Michiya Kadota; "Kurita" below) and Hitachi, Ltd. (Head office: Chiyoda-ku, Tokyo; Representative Executive Officer, President & CEO: Keiji Kojima; "Hitachi" below) have launched a collaborative creation for DX to manage steel mill raw material yards.

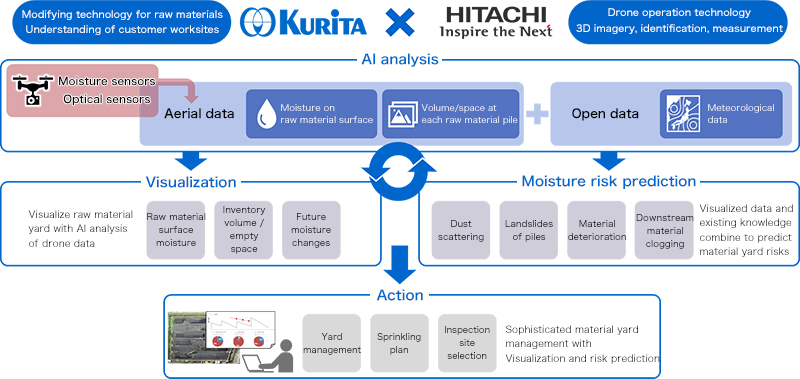

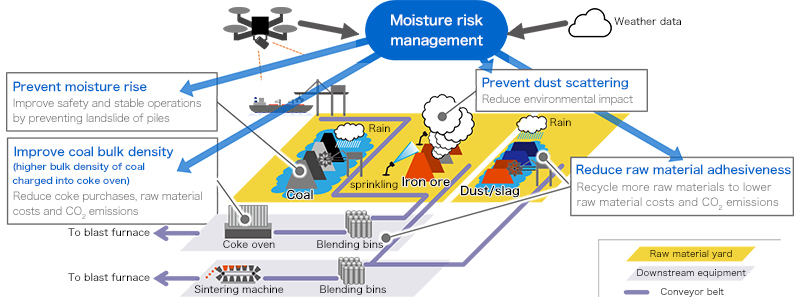

Through the co-creation, the two companies will develop new solutions by combining Kurita's techniques and knowledge concerning modifying technology for raw material*1 and extensive knowledge on steel mill processes with Hitachi's drone operation technology and AI-powered data analysis technology and knowledge. Specifically, drones equipped with moisture sensors will fly over steel mill yards for storing piles of raw materials unloaded from ships to measure the moisture of each pile. The data collected will present a picture of the general status at these large sites. That data will be combined with related meteorological data on a cloud platform for AI analysis that will generate predictions of changes in raw material moisture arising from evaporation and rainfall. Providing an advance look at raw material particle dispersal and the impact on downstream equipment for such as sintering processes and coking*2 will allow for the management of risks arising from moisture.

Visualizing these risks from moisture will help to apply modifying technology for raw material in a timely manner, improve productivity and safety at steel mills, and reduce CO2 emissions by using less fuel for equipment in downstream processes.

To make the solutions feasible, Kurita and Hitachi will jointly develop algorithms for predicting changes in raw material moisture, move forward with testing at steel mills in Japan, and in the future, consider applying the solutions to other business sectors and rolling them out globally.

■Background, Co-creation Details

In recent years, there has been a depletion of global supplies for high-quality raw materials used in producing steel, such as iron ore and coal. Therefore, an increasing share of raw materials is more challenging to work with. Since steel mills store much of these raw materials outdoors, increased moisture from rain and other factors poses problems by reducing transportation efficiency and causing landslide of piles of raw materials. This situation demands more sophisticated raw material yard management.

While providing modifying technology for raw material and consultations to steel mills, Kurita has identified the moisture in the raw materials as the cause of many of the problems arising at raw material yards and in equipment downstream. The Company has since studied optimal approaches to raw material yard management.*3 Meanwhile, as Hitachi has utilized Lumada*4 technologies and solutions to accelerate digital innovation in the drone industry to roll out proprietary services in such fields as infrastructure inspection, measurement, and disaster management,*5 the Company has provided inventory management systems employing drones for raw material yards.*6

By developing techniques that use drones to measure moisture on each raw material pile surface and an algorithm that predicts changes in moisture from a combination of meteorological and raw material data, Kurita and Hitachi are now launching a co-creation toward new solutions that apply these techniques.

■The Co-creation's Value for Customers

1. Gain a detailed understanding of worksites by analyzing data and visualizing each raw material pile

Drones equipped with optical and moisture sensors will perform aerial photography to gather real-time data on each raw material pile's volume and surface moisture. That data will be stored on a cloud platform. AI will analyze both the data from raw material measurements and open-source meteorological data to predict and visualize future changes in moisture. This will provide an advance understanding of risks caused by moisture, such as particle dispersal from each raw material pile and raw material clogs in downstream equipment.

This solution will decrease workloads. For example, it will create logs of information on raw material that has been inputted manually, including the volume of each raw material pile in inventory, which has typically been confirmed with visual checks based on the experience of skilled workers. The solution will also provide an efficient way to understand properties that are difficult to confirm on a frequent basis. This includes the moisture in each raw material pile and the need of modifying agents for raw materials, such as water-proof coating agents that prevent moisture accumulation.

2. Improved productivity and lower environmental impact through the timely application of modification techniques in response to changes in moisture

Visualizing the risks caused by moisture will enable action such as optimal plans of sprinkling system to prevent particle dispersal and the selection of locations to inspect. This solution will also allow for the timely application of various modifying technologies for raw material, such as those that prevent the accumulation of moisture in raw materials and reduce the raw materials' adhesiveness to equipment. Making raw materials easier to handle by suppressing their deterioration will improve productivity and safety at steel mills, while helping to reduce carbon emissions by lowering the amount of fuel used in equipment during downstream processes.

■Future Outlook

Kurita and Hitachi will work on developing technologies and solutions for DX in raw material yard management that improves productivity and reduces the environmental impact at steel mills. Furthermore, the companies will conduct joint demonstration tests at steel mills to improve Kurita's raw material moisture detection technology and Hitachi's AI analysis technology so as to provide solutions to other business sectors and roll them out globally.

Notes

- *1Modifying technology for raw material: Technology for applying the proper amount of chemicals that make highly moist steelmaking raw materials easier to use, such as water-proof coating agents that prevent moisture accumulation in outdoor settings from rain.

- *2 Coke: A lump of carbon extracted from coal that has been baked through dry distillation.

- *3 See the Kurita website: Advance Industrial Production Technologies : Ultrapure water supply, Water Treatment Facilities & Chemicals : The Kurita Group - Kurita Water Industries Ltd.

- *4 Lumada: A collective term for solutions, services and technologies using Hitachi's advanced digital technologies to generate value from customer data and accelerate digital innovation

https://www.hitachi.com/products/it/lumada/global/en/index.html - *5 See the Hitachi website's Drone Solutions page: https://www.hitachi.co.jp/Div/jkk/global/drone/index.html

- *6 Hitachi Stockpile Management System with utilizing drones for raw material stockpile yard: A cloud service providing one-stop support for optimized inventory management that eliminates excess inventory by efficiently identifying onsite inventory status through the timely collection of actual data through aerial photography by drones, the accumulation of data on a cloud platform, and AI analysis and visualization of raw material piles. Hitachi news release (December 2, 2021; in Japanese)

https://www.hitachi.co.jp/New/cnews/month/2021/12/1202.html

■About Kurita

Based on our corporate philosophy to "study the properties of water, master them, and create an environment in which nature and humanity are in harmony," Kurita provides customers with value to realize a sustainable society through our business activities in water and the environment. Seeing CSR as central to our business management, we operate under the four themes of "Solve issues related to water resources," "Realize sustainable energy use," "Reduce waste," and "Advance industrial production technologies" to create value throughout society and provide customers with products, technologies, and a business model making major contributions to water conservation, reducing carbon emissions, and reducing waste.

In fiscal 2021 (the year ended March 2022), Kurita had consolidated sales revenue of 288.2 billion yen. As of March 2022, the Company has 70 consolidated subsidiaries employing 7,661 people worldwide.

Visit the Kurita website for more information (https://www.kurita.co.jp/english/index.html).

■About Hitachi, Ltd.

Hitachi drives Social Innovation Business, creating a sustainable society with data and technology. We will solve customers' and society's challenges with Lumada solutions leveraging IT, OT (Operational Technology) and products, under the business structure of Digital Systems & Services, Green Energy & Mobility, Connective Industries and Automotive Systems. Driven by green, digital, and innovation, we aim for growth through collaboration with our customers. The company's consolidated revenues for fiscal year 2021 (ended March 31, 2022) totaled 10,264.6 billion yen ($84,136 million USD), with 853 consolidated subsidiaries and approximately 370,000 employees worldwide.

Visit the Hitachi website for more information (https://www.hitachi.com/).

END

■For inquiries, contact

Section I, Marketing Department I, Innovation Division, Kurita Water Industries Ltd.

Mail: kwi_marketing_press@kurita-water.com