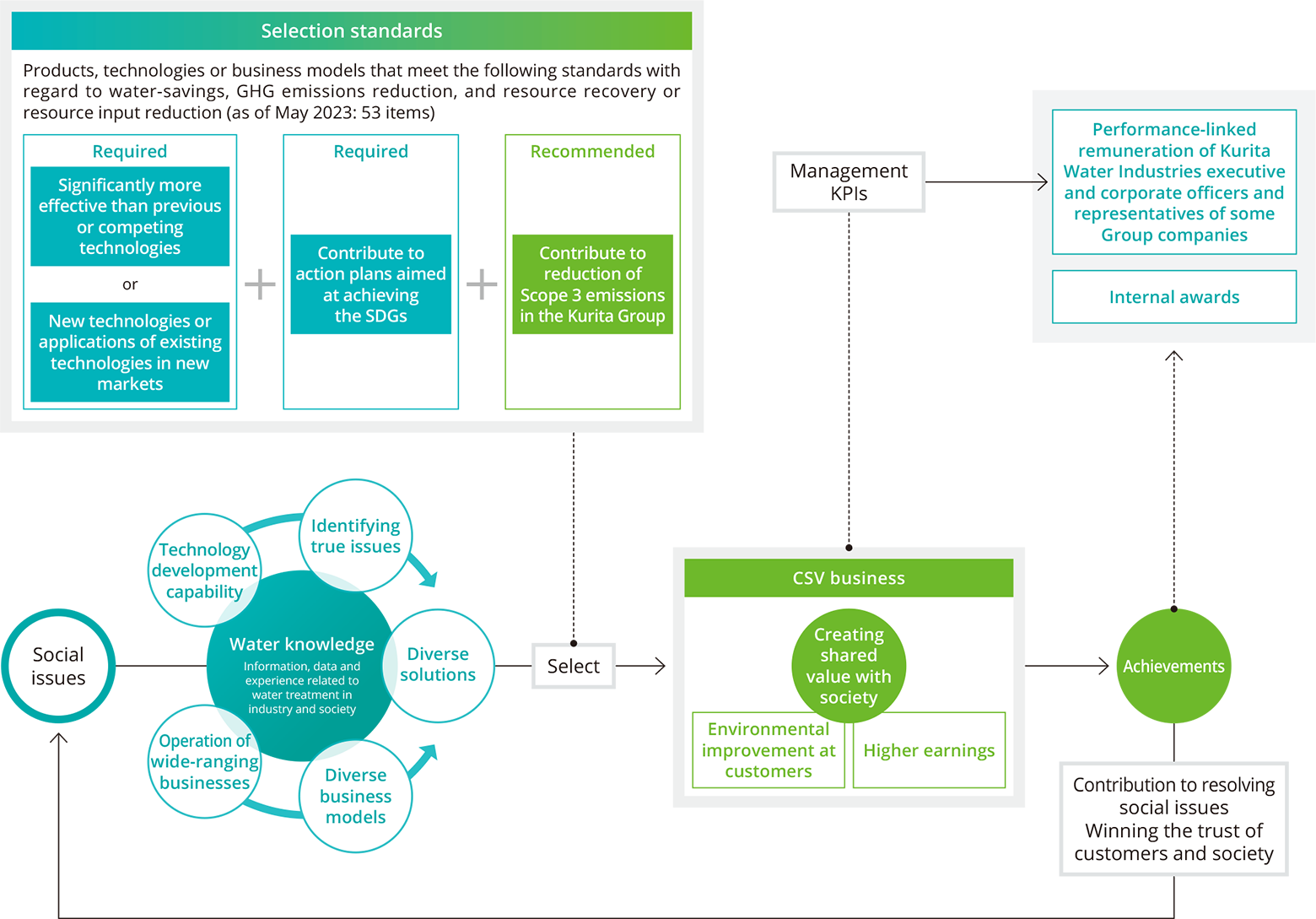

The Kurita Group’s CSV Business

The Kurita Group has defined products, technologies, or business models that

contribute significantly to water-saving, greenhouse gas (GHG) emissions

reduction and resource recovery or reduction of resource inputs compared to

previous levels as the “CSV business,” and has expressed these advantages as

respective coefficients. The reduction of environmental impact from customers’

operations is calculated based on these CSV business coefficients and

application results. The CSV business is also constantly reviewed in light of

the development status of more competitive products, technologies, and business

models.

The CSV business is an initiative that links the indicators for

Shared Value Themes of the Kurita Group’s materiality—solve issues related to

water resources, contribute to the realization of a decarbonized society, and

contribute to building a circular economy society—with the financial targets for

PSV-27. Meanwhile, metrics indicating the contribution of our CSV business to

customer performance in water saving, GHG emissions reduction, resource

recovery, and resource input reduction are used to evaluate the performance of

personnel eligible for performance-linked remuneration, such as the executive

and corporate officers of Kurita Water Industries and the representatives of

some Group companies.

Representative examples

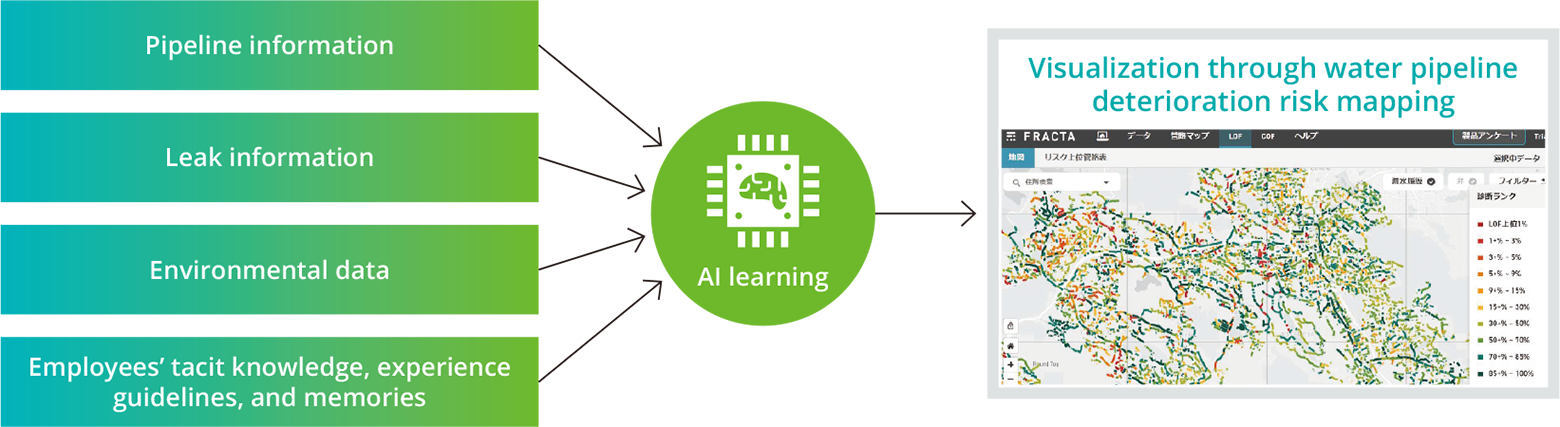

AI-based Water Pipeline Deterioration Diagnosis System

Water pipelines are a vital infrastructure supporting people’s lives, and they must be replaced periodically based on the number of years since installation. However, most water pipes are buried underground, and their deterioration rate varies depending on site-specific factors such as the soil environment, traffic conditions, and gradient. It is therefore difficult to prevent water leaks caused by pipe deterioration simply by judging based on the number of years since installation. Kurita’s AI-based water pipeline deterioration diagnosis system provides a predictive diagnosis of deterioration by providing an AI with various information such as water pipeline information, local environmental data, and past leak information. The system enables efficient replacement of water pipelines and investigation of leak points, helping to control the occurrence and volume of leaks.

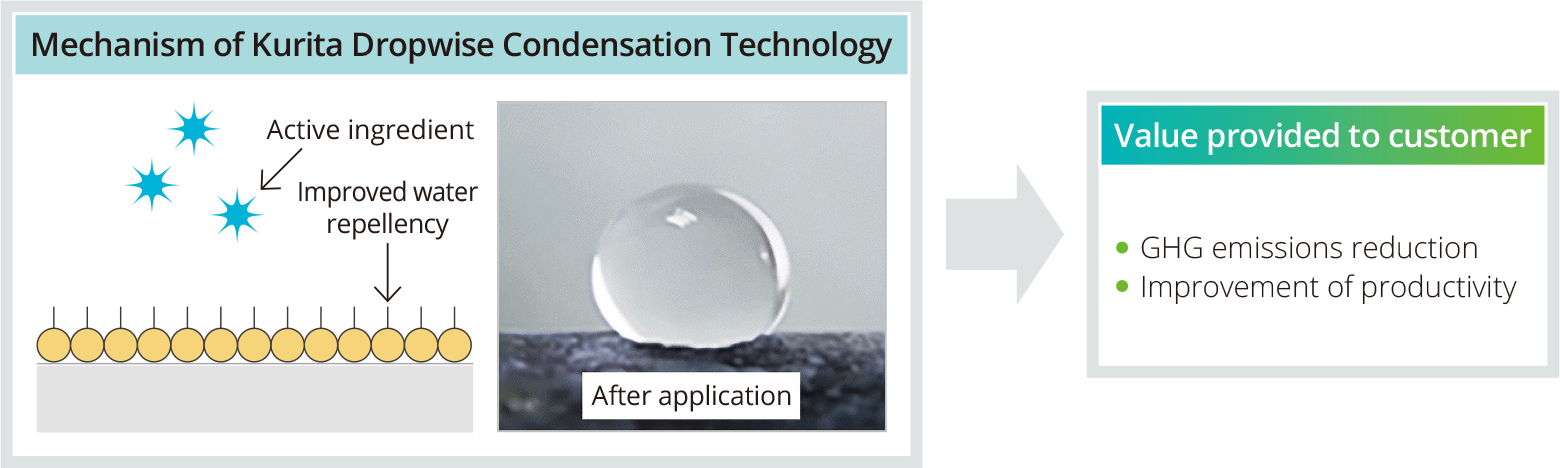

Kurita Dropwise Condensation Technology

The production process at many manufacturing plants uses heat exchangers to heat substances with steam. The steam transfers its heat to the treated substance via the metal surface of a heat transfer plate and then condenses, forming a film of water on the metal surface, which is known to be a factor in blocking heat transfer. Kurita Dropwise Condensation Technology induces water-repellent properties in the heat transfer surface of the heat exchanger, thus preventing the formation of a water film and boosting heat transfer efficiency. This in turn improves productivity and reduces the volume of steam required, which contributes to energy-saving. As the technology works by simply adding water treatment chemicals to the steam, it allows manufacturers to reduce GHG emissions without needing to stop production equipment or make a large-scale investment.

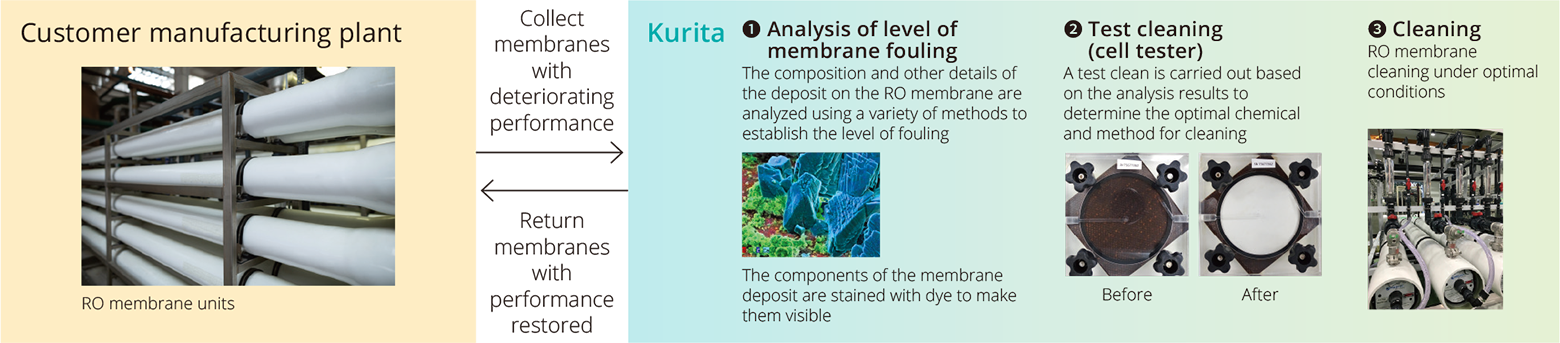

Off-Site Cleaning and Restoration (OSCAR)

Reverse osmosis (RO) membranes have an important function in removing the impurities contained in water and have a wide range of applications, for instance in ultrapure water production and wastewater reclamation. With continued use, RO membranes become clogged with deposits, which lowers performance, and they therefore require periodic cleaning. Conventional cleaning processes were unable to restore high performance, but with OSCAR, performance after cleaning is almost as good as new. This technology is owned by Avista Technologies, Inc., which was acquired by M&A. By enabling RO membranes to be reused and restoring their performance, and thereby achieving reduction of the pump energy required, it contributes to resource recovery and GHG emissions reduction.

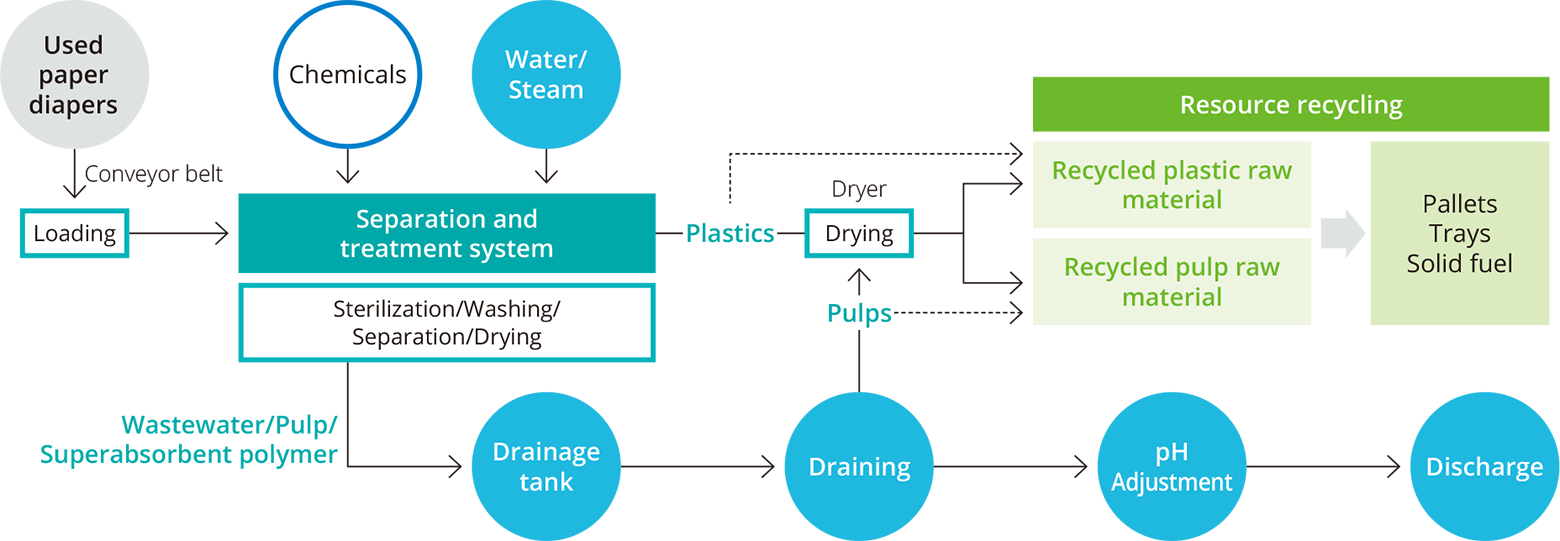

Used Diaper Separation and Treatment System

Used paper diapers in Japan are mainly disposed of as general waste by incineration facilities operated by waste disposal companies and local municipalities. As Japan becomes a super-aged society, the volume of waste is expected to increase. Kurita developed a system that washes and separates used diapers for recycling. By adding a bag-tearing function to the system, it is able to process used paper diapers that are sealed inside plastic bags, improving hygiene and operating efficiency. Used paper diapers are washed and disintegrated by the device, then plastics are separated out from the treatment water, which contains pulp. The separated components can be used for application such as solid fuel or recycling plastic.

This website uses the names of products and services in Japan. Please note that product and service names differ in other countries.