2023

October 27, 2023

Kurita Receives the Sasaki Award from the Japan Technical Association of the Pulp and Paper Industry for FINE STEAM™ based on Kurita Dropwise Condensation Technology

Kurita Water Industries Ltd. (Head Office: Nakano-ku, Tokyo; President: Hirohiko Ejiri; hereinafter "Kurita") announced that it has received the Sasaki Award from the Japan Technical Association of the Pulp and Paper Industry (hereinafter "Japan TAPPI") in recognition of FINE STEAM™, a dryer treatment agent for improving heat transfer efficiency that is intended for the papermaking and pulp industry and is based on Kurita Group's original Kurita Dropwise Condensation Technology. This is the second time Kurita has received the Sasaki Award, having been granted the award in FY2019 for its System for Improving Productivity, Operating Efficiency, and Environmental Hygiene.

Japan TAPPI was established to encourage the development of the paper and pulp industry and associated industries through technological and academic exchanges between them. Its members include papermaking companies, relevant public offices, national and public research institutions, independent administrative agencies, and suppliers related to manufacturing equipment and chemicals. The Sasaki Award that Kurita received is granted by Japan TAPPI to companies and business operators that have contributed to the paper and pulp industry through remarkable achievements in technology or in research and development. It is one of the most prestigious awards in the industry. This year, two companies including Kurita were granted the award.

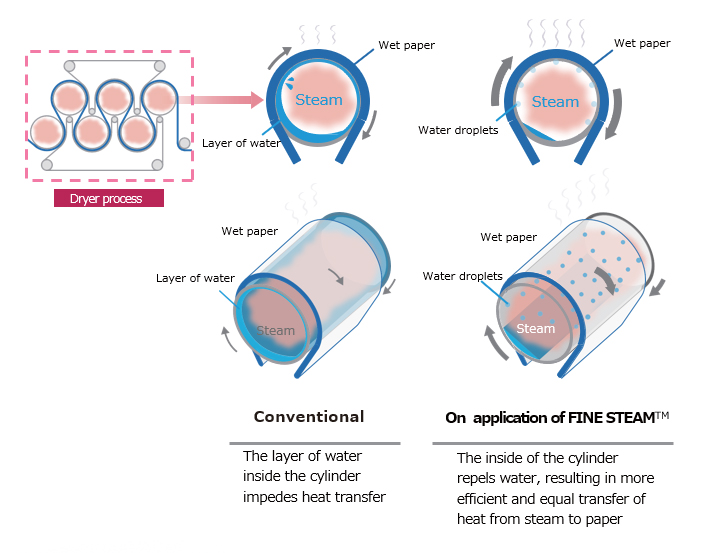

In the dryer section of the paper manufacturing process, a large amount of steam is used to dry the wet paper and a layer of water resulting from the condensation of steam is formed inside the cylinders in this section. This layer of water, however thin, significantly lowers the heat transfer efficiency, resulting in slower production, energy loss due to increased steam usage, and deterioration in quality. FINE STEAM™ is a specialty chemical which creates a water repellant film inside the cylinders in the drying section and stops the layer of water from forming. The award was granted in recognition of the fact that application of this chemical will prevent the formation of a layer of water inside the drying cylinders, delivering improvement in the heat transfer efficiency from steam to paper.

The additional utilization of a chemical dosing system incorporating Kurita Group's S.sensing™ technology would automatically control chemical dosing and deliver just the right amount of chemical to keep the inside of the cylinders water repellant, thereby maintaining a situation in which the effects in terms of improving productivity and conserving energy are maximized. The cloud-based remote monitoring service S.sensing™ WEB could also be introduced to enable monitoring of chemical dosing and the sharing of data with the customer.

FINE STEAM™ is based on Kurita Dropwise Condensation Technology, which gives water repellent properties to the metal surfaces of heat exchangers to remove the layer of water and improve heat transfer efficiency.

This technology has been installed in more than 300 facilities across a wide range of industries around the world. It has been applied in the manufacturing of various types of paper including regular paper such as newspaper, household paper products such as tissue paper, and corrugated board. Kurita has also verified its effects in improving productivity and reducing energy consumption in other industries such as the steel, petrochemicals, chemicals and rubber industries. Going forward, Kurita aims to deliver plant-wide energy efficiency improvements and contribute to more efficient energy usage in industry through application of this technology to a wider range of industries and equipment.

Under the Medium-term Management Plan PSV-27 (Pioneering Shared Value 2027), Kurita defined "Solve issues related to water resources," "Contribute to the realization of a decarbonized society" and "Contribute to building a circular economy society" as Kurita Group's Materiality (Shared value themes), and is focusing on creating and providing shared value with society and working with customers to held realize a sustainable society.