2013

December 5, 2013

Kurita Launches S.sensing – Water Treatment Management Service that Enables Optimal Water Treatment on a Real-time Basis

Kurita Water Industries Ltd. (Head Office: Nakano-ku, Tokyo; President: Toshiyuki Nakai) is pleased to announce its launch of S.sensing, a new water treatment management service utilizing sensing technologies, as a part of its water treatment chemicals business.

The service applies a system combining Kurita’s unique technologies for measurement, analysis, control, and monitoring to subject facilities that use water treatment chemicals, such as cooling water systems and wastewater treatment facilities. It controls chemical dosing on a real-time basis in accordance with changes in water quality. It also enables remote monitoring of water treatment effects and sharing of this information with customer.

In addition to monitoring water quality data, the amount of chemicals dosed, remaining amount of chemicals, and other aspects, which were features available with previous services, the new service analyzes and automatically controls the effective concentration and water treatment effects of chemicals, thereby allowing optimal and more effective water treatment. Through provision of S.sensing, Kurita will identify customers’ issues related to water and the environment and promote higher-quality solutions.

With S.sensing, Kurita will respond to customers’ needs by applying its unique sensing technologies developed for diverse fields to widely provide services, including a service for optimizing water treatment of cooling facilities by adjusting chemical concentration to avoid excesses or deficiencies, a service that stabilizes the quality of treated water and reduces the cost of wastewater treatment facilities, and a service for improving the productivity of paper and pulp production processes.

- *Please refer to the supplementary document for specific details of S.sensing services in wastewater treatment and paper manufacturing processes.

These measurement data and results of controls are also automatically collected via a communication line, allowing remote monitoring of their trends. Customers can conduct online checks of the longitudinal data and reports and graphs showing automatically analyzed data.

The services also let Kurita share information with customers about water treatment management status, its effect, and trends in their changes over time, on a real-time basis. This means Kurita will be able to more proactively predict trouble, create more efficient water treatment specifications, and offer suggestions for higher productivity and reduction of environmental impact. Kurita will promote application of S.sensing in various markets in Japan and other countries and promote customer-based water treatment management services.

- *S.sensing is a trademark of Kurita Water Industries Ltd.

Supplementary document: S.sensing services (for wastewater treatment and paper manufacturing processes) and screens for managing water treatment status with S.sensing.

S.sensing services (for wastewater treatment and paper manufacturing processes)

- Wastewater treatment

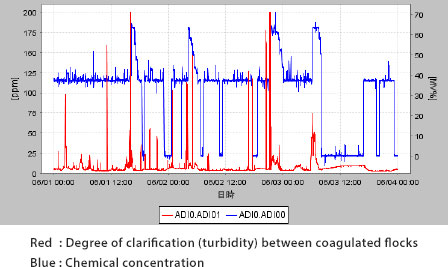

The S.sensing OS, a sensing device incorporating a coagulation sensor that detects the status of coagulated flocks in the coagulation treatment process on a real-time basis, is installed at the customer’s work site to control the amount of dosing of inorganic coagulants, etc. The sensor uses laser scattering light to measure the coagulation status. It is capable of stably measuring the status even in high-concentration wastewater containing both coagulated flocks and tiny suspended solids. A standard way of monitoring wastewater is to monitor the turbidity of final effluent or highly treated water. Kuripitari can be installed in the rapid mixing chamber of the preliminary step, allowing analyses and control with minimum time lag, even in a rapid change in the impact on water quality, thus maintaining stable coagulation status.

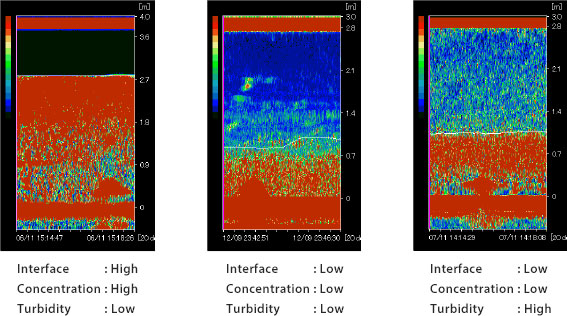

In active sludge treatment processes, a sedimentation monitor that ultrasonically monitors the inside of the settling tank, is used for measuring the status and changes of sludge on a real-time basis. This yields benefits such as helping improve the management of active sludge, preventing trouble, and saving energy.

With these devices, Kurita enables total cost reduction for customers in ways such as letting them stabilize their wastewater treatment, optimizing chemical dosing, and saving labor for water treatment and operational management. - Paper manufacturing processes

A large amount of water is used in the manufacturing of paper. The quality of water used in the processes greatly influences the operating efficiency and product quality, so appropriate water treatment is required for each process.

S.sensing applies S.sensing BU, a sensing device for real-time measurement of water quality elements essential for water treatment management in paper manufacturing processes. This monitors water quality data in each process to analyze the correlation with data on customer operations and quality.

By utilizing results of the analyses based on Kurita’s expertise in water treatment, the service enables the identification of water quality elements that are highly influential for product quality and operational efficiency, and conducts precise control of agents for treating microorganisms and chemicals for paper manufacturing processes, such as polymer, to maintain optimal water quality, thereby helping customers ensure stable operations and reduce the occurrence of defective products.

- *Kuripitari and Kurisonic are trademarks of Kurita Water Industries Ltd.

Screens for managing water treatment status with S.sensing

- Cooling water treatment

- Wastewater treatment

- Status of sludge