Membrane separation and filtration technologies are used to remove suspended solids, fine particles and dissolved substances (organic matter, ions) from water using the pores of separation membranes made from various materials such as organic compounds and inorganic compounds.

Industrial water or well water contains suspended solids because is not treated at purification plants in the same way as the drinking water supply. In water purification, water is passed through a filter medium such as sand and then a membrane needs to be used to separate and remove even finer suspended solids.

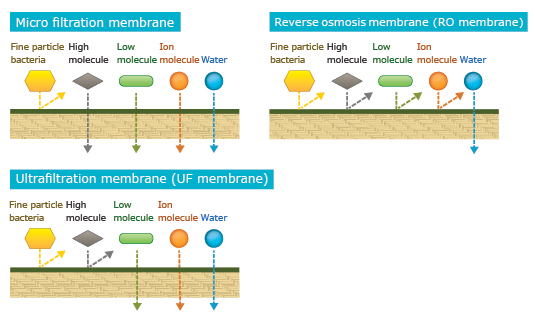

Membrane separation and filtration technologies are technologies that selectively allow substances to move through membrane pores and use differences in the pressure of the solution that comes into contact with the membrane and the different pore sizes of each membrane material to sieve and separate out substances. The type of membrane and its method of use vary depending on the size of the substance to be separated, and there are microfiltration membranes for separating suspended solids, bacteria and fine particles, ultrafiltration membranes for separating proteins, oxygen and bacteria, and reverse osmosis membranes for separating even smaller substances such as low molecular weight compounds and ions.

Kurita uses membrane separation and filtration technologies to provide the optimal membrane treatment devices according to the quality of the raw water and the required water quality after treatment.