2017

September 5, 2017

KURITA Launches CETAMINE® JP Series in Japan

- An Eco-Friendly, Safe Water Treatment Chemical for Middle & High Pressure Boilers which Uses Film Forming Amine Technology to Offer a Single Liquid for Multiple Problems -

Kurita Water Industries Ltd. (Head Office: Nakano-ku, Tokyo; President: Michiya Kadota) is pleased to announce that it has started selling a new version of CETAMINE®, a water treatment chemical for intermediate and high pressure boilers acquired through M&A in Europe in 2015, in the Japanese market under the name CETAMINE® JP Series.

CETAMINE® is a Kurita Group product which uses Film Forming Amine (FFA) to prevent the "corrosion of pipes" in power plant boilers, and its effectiveness is attracting attention worldwide. Already delivered to more than 1,000 customers in Europe, CETAMINE® offers numerous advantages not only extending the life of the piping, ensuring the safe and stable operation of units but also reducing energy costs and improving productivity. The newly launched product CETAMINE® JP Series has all the basic features of CETAMINE® and contains no materials regulated under Japan's Poisonous and Deleterious Substances Control Act and the Pollutant Release and Transfer Register (PRTR). Kurita is promoting application of CETAMINE® JP Series in the Japanese market as an eco-friendly, safe water treatment chemical that contains no Hydrazine, which has mutagenesis.

Preventing the corrosion failure of carbon steel pipes (*) in condensate-feed water systems is essential for the stable operation of intermediate and high pressure boilers at power plants and is one of the most important issues for customers. Until now it was common practice to control corrosion by keeping the pH of the boiler water and the feedwater/condensate at a high level. However, this approach has a weak point, for example, an excessively high pH causes corrosion of the copper-based material, and this was an inadequate solution. In contrast, CETAMINE® JP Series prevents corrosion because it contains a Film Forming Amine which adsorbs onto the metal surface and forms a fine aquaphobic film layer, preventing the water from coming in direct contact with the metal surface. CETAMINE® JP Series also contains a neutralizing amine, thus adjusting pH to the optimum level and providing highly effective corrosion control (reducing the corrosion rate by around 80% compared with the effects of our previous treatments).

CETAMINE® JP Series also improves the work environment of boiler operators, and reduces the labor involved in plant operating work. Previously it was common to treat boiler water with three agents: a boiler compound, a oxygen scavenger and a pH adjuster for the condensate and feedwater. However, CETAMINE® JP Series is a reliable and highly effective treatment which integrates all these functions into a single liquid product, meaning that it is not necessary to control the concentration of multiple chemical agents and dissolve and dilute the power boiler compound. CETAMINE® JP Series can also be injected into the boiler water system at any point and requires a single low-cost, low-pressure and low-spec. chemical injection unit, thus bringing significant advantages in terms of cost savings for maintenance and operation.

Kurita has begun applying this product in industrial power generating boilers with steam pressure 10MPa and higher, and in biomass fuel fired power generation and waste heat recovering power generation boilers. In Japan, Kurita is still building its experience in water treatment chemicals using Film Forming Amine for intermediate/high pressure power boilers, and we aim to further expand our share by making this product widely used in diverse sectors in the future.

In the boiler water treatment market, Kurita developed DReeM Polymer™, a material of water treatment chemicals for low pressure boilers in 2014, and built up a track record and experience for its application. With DReeM Polymer™ and its new product CETAMINE® JP Series for intermediate and high pressure boilers, Kurita will continue to work on initiatives which will contribute to the stable operation of boiler plants and the total cost reduction.

- Note:

- At power plants (intermediate and high pressure boilers), wall thinning of pipes due to Flow Accelerated Corrosion (FAC) occurs especially in places where the flow of water inside the pipes is high velocity and disturbed. Corrosion can cause piping rupture, leading to suspension of boiler operation and injury.

SUPPLEMENTARY INFORMATION

■Features of CETAMINE® JP Series

- Film Forming Amine and neutralizing amine have the effect of controlling Flow Accelerated Corrosion (FAC) in condensate feedwater systems, and are also effective in preventing corrosion of copper-based materials.

- Condensate Condenser-feedwater systems and boilers can be treated with one product, removing the need to control multiple chemical agents and dissolve and dilute boiler compound. Only a single chemical injection unit is required.

- CETAMINE® consists entirely of volatile substances, and there is no scale depositionig on the turbine due to carryover.

- CETAMINE® JP Series contains no hydrazine, which has mutageniesis, making the work environment safer.

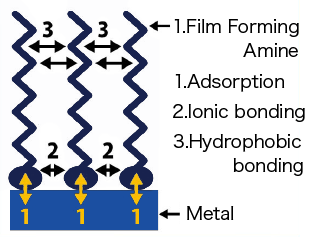

■Corrosion control mechanism of Film Forming Amine

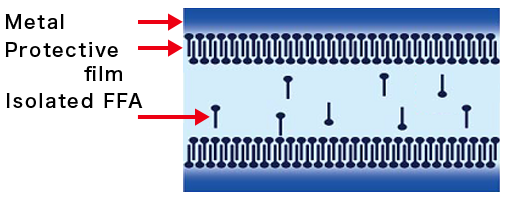

- Film Forming Amine adsorbs onto the metal surface (see 1 of Fig. on left below), forming ionic bonds with metal (see 2 of Fig. on right) and strongly adsorbing onto the metal through hydrophobic bonding (see Fig. 3 on left). This then forms a protective film layer (anticorrosion film), preventing the metal from direct contact with the water.

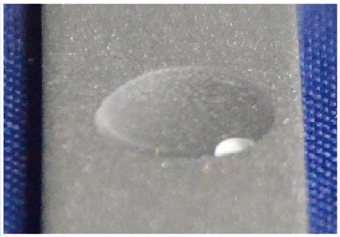

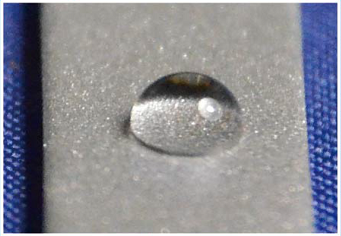

※Following formation of the protective film layer through adsorption of the FFA, the metal surface shows water repellency.

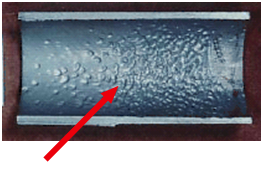

(The photographs below show a comparison of water repellency. The photograph on the left shows an untreated sample, and the photograph on the right shows a CETAMINE®treated sample.)

■Example of Flow Accelerated Corrosion (FAC)

Thinning of pipe caused by FAC (higher risk of pipe breaking if thinning is not prevented)