Under "MVP-22(Maximize Value Proposition 2022)", the medium-term management plan that was launched in this April, Kurita Water Industries Ltd. (Head Office: Nakano-ku, Tokyo; President: Michiya Kadota; hereinafter "Kurita") is focusing on creating shared value with society, identifying "Solve issues related to water resources", "Realize sustainable energy use", "Reduce waste" and "Advance industrial production technologies" as priority issues.

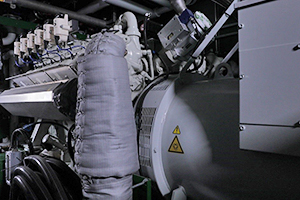

Fuji Clean Co., Ltd. (Head Office: Ayauta-gun, Kagawa; President: Kazuo Baba; hereinafter "Fuji Clean"), a specialist in the treatment of industrial waste, recently finished building facilities using Kurita's vertical dry-methane fermentation technology, Kurita DRANCO PROCESS™, that will help "Realize sustainable energy use." Operations are scheduled to begin from October. The facilities will make effective use of biogas produced from industrial waste and municipal waste through methane fermentation as fuel for power generation and boilers, and digestate will be treated incineration facilities. The reactor is Japan's largest vertical, dry-methane fermentation reactor (3,000m3) and Fuji Clean expects adoption of the technology to have the effect of reducing CO2 emissions by 10,000 tons per year.