2016

November 29, 2016

Kurita Steps Up Proposals on General Water Treatment for Small and Midsize Painting Booths to Open Up New Markets for Water Treatment Chemicals

Proposing one-stop solutions to problems from paint tack-free treatment to odor and other environmental improvements

Kurita Water Industries Ltd. (Head Office: Nakano-ku, Tokyo; President: Michiya Kadota; hereinafter "Kurita") is pleased to announce that it will step up its proposals on solutions to water and environmental issues to customers using small and midsize painting booths in a wide variety of domains including automotive parts, furniture, electric appliances, metal products and plastic products with the use of its technologies and expertise nurtured with water treatment chemicals for automobile painting booths. By taking this action, Kurita will endeavor to open up the market of small and midsize painting booths and to expand its Water Solutions business in Japan and around the world.

Kurita offers an array of water treatment chemicals for different purposes in a bid to resolve customers' issues with large-sized painting booths at automobile assembly plants. In June 2015, Kurita released the KURITA™KS-3070 chemical for small and midsize painting booths, adding it to the lineup. This paved the way to helping resolve the problems facing more customers who own painting booths.

Many small and midsize painting booths use oil-based paint (solvent-based paint), and its viscosity poses problems. The adhesion of paint to the inside of painting booths, circulating water piping, pumps and other facilities leads to the deterioration of painting quality, the stoppage of the production line and other serious problems. The increase in the frequency of cleaning the equipment and the impact on the wastewater treatment systems poses another issue.

In response to these issues, the KURITA™KS-3070 exhibits the unrivalled long-lasting effect of removing the viscosity of oil-based paint to prevent the paint from sticking to equipment. With conventional water treatment chemicals, the tack-free effect does not last long enough. If they are added excessively, foam is generated. It is therefore necessary to continuously inject them with the use of a chemical dosing system. With the KURITA™KS-3070, there is no concern about foaming. It involves easy management and enables one-time injection, eliminating the need to install a chemical dosing system. These advantages are accepted by customers owning small and midsize painting booths, and since last year sales of the KURITA™KS-3070 have been increasing, chiefly to customers to whom it had yet to be delivered. It is also being adopted by Chinese automotive component manufacturers and others.

In addition, Kurita is working to provide comprehensive solutions on the basis of the KURITA™KS-3070 to problems concerning small and midsize painting booths. For example, the frequency of cleaning water curtains in painting booths to remove accretions is reduced by applying anti-scale agents. To deal with odor due to the sedimentation of surplus paint and the decay of circulated water, deodorizing technologies opened up in wastewater treatment are introduced. We therefore offer optimal proposals to customers, combining different chemicals to help them reduce the environmental impact and increase productivity.

Amid growing demand for services responding to a wide range of customer issues while paint types and painting booth structures are diversifying, Kurita will be focusing its energy on the cultivation of the new market of small and midsize painting booths in addition to the existing market of large ones in automobile and other factories. For a wide variety of customers, not only in Japan but also in China, Southeast Asia and other overseas markets, Kurita will step up its proposals of its unique comprehensive water treatment for painting booths in a bid to achieve sales of 1.2 billion yen from these efforts within three years.

Related Press Release:

Kurita Develops the New Kuristuck Series Water Treatment Chemicals to Help Reduce the Environmental Impact and Improve Productivity at Automobile Factories and Other Facilities (June 29, 2015)

(Additional information)

■ Water Treatment in Small and Midsize Painting Booths

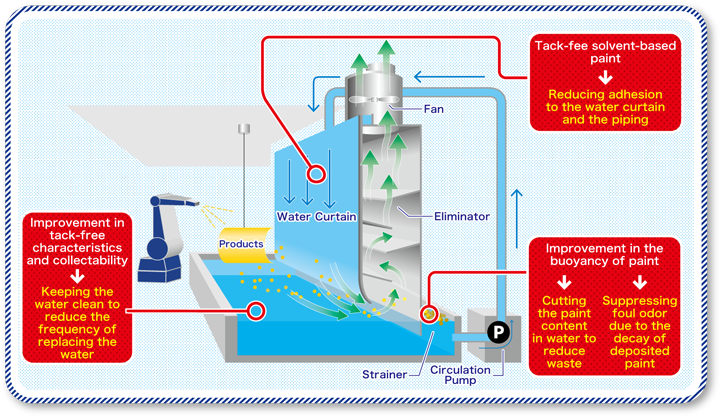

In many of the small and midsize painting booths concerned, paint is sprayed onto products in the form of mist. In this event, surplus paint that does not adhere to the products is collected by means of a thin wall of water flowing in the form of a curtain, to prevent the paint from flying into the outer air. The water used for water curtains has water treatment chemicals added in order to make the paint tack-free and to separate and collect it. The treated water is circulated and reused.

However, when the process of making the paint tack-free and separating and collecting it is inadequate, the paint and scales adheres to the water curtains. This means that the equipment must be cleaned more often and that products may become defective due to the rebound of paint caused by the accretions and splashes of water. In addition, the decay of excessive paint and circulated water may cause a foul odor. For small and midsize painting booths, many different problems related to water treatment need to be resolved.

■ Introduction of the KURITA™KS Series and Chemicals for Small and Midsize Painting Booths

<KURITA™KS Series>

The KURITA™KS Series is Kurita's lineup of water treatment chemicals for treating paint used in the painting booths of customers' factories. Amid the changes in the structure of painting booths and paint types, Kurita develops products with different functions suited to customers' needs, adding them to the lineup.

<Chemicals Used in Small and Midsize Painting Booths>

| Product Name | Features |

|---|---|

| KURITA™KS-3070 (*KURITA™KS Series) |

|

| Anti-scaling agent : …KURITA™GZ Series, etc. |

|

| Deodorizing agents: …KURITA™DO Series, etc. |

|