2013

July 29, 2013

Kurita Expands the Range of Application of its KURITIGHT Series of Extremely Safe Boiler Water Treatment Chemicals, which are Produced Solely from Food and Food Additives, by Adding New Products to the Line.

Kurita Water Industries Ltd. (Head Office: Nakano-ku, Tokyo; President: Toshiyuki Nakai) is pleased to announce that it has added three new products to the KURITIGHT series of extremely safe boiler water treatment chemicals, which are produced solely from food and food additives*1.

In 2002, Kurita began selling the KURITIGHT series to customers in the food and beverage industries, where top priority is given to product safety. Since then, the products have been utilized by customers from a wider range of industries, meeting their expectations in terms of quality. In recent years, there have been an increasing number of customers who wish to comply with FSSC22000*2 and HACCP*3. To meet the increasing demand for safety, Kurita has expanded the range of applications of KURITIGHT and launched new products with enhanced treatment performance into the market.

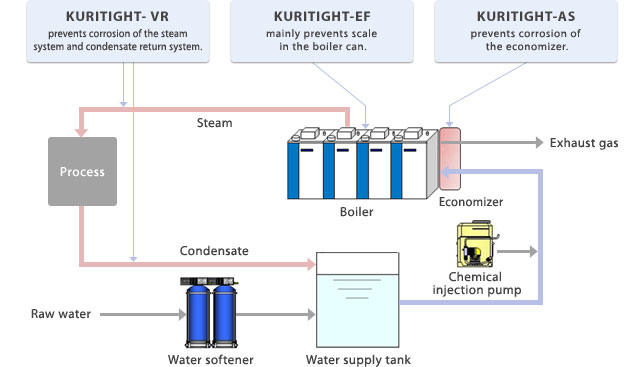

Specifically, Kurita has launched three new products: KURITIGHT-VR, a boiler water treatment chemical for steam system and condensate return system produced from food and food additives that was the first to be successfully commercialized in Japan; KURITIGHT-EF, which produces a stable effect to prevent the adhesion of scale, which causes numerous problems inside the special circulation boilers and other equipment; and KURITIGHT-AS, which was developed as a chemical to prevent the corrosion of economizers*4 for boilers. These products ensure extremely safe chemical treatment throughout an entire boiler plant, which includes not only the boiler but also the steam system, condensate*5 return system, and even ancillary facilities.

Kurita undertakes comprehensive quality control in the manufacture of KURITIGHT to prevent the introduction of foreign objects and feedstock for other products into the manufacturing processes. For example, it has established exclusive manufacturing lines for KURITIGHT to ensure comprehensive hygiene control. Kurita also checks the quality of raw materials and manufactured products and analyzes their components during each of the processes from the receipt of raw materials to manufacturing, inspections, and shipment. What is more, after the shipment of the products, Kurita discloses the results of the pre-shipment inspections and product information to customers by using a traceability system.

There are increasing numbers of customers placing emphasis on the safety of the ingredients of treatment chemicals other than those for boilers. In response, Kurita is expanding its lineup of products made from extremely safe materials for other water treatment processes, such as the treatment of cooling water.

Through these initiatives, Kurita will provide customers such as food and beverage factories, pharmaceutical factories, and hospitals with water treatment solutions that meet their needs for safety and security, as well as contributing to their facility maintenance, stable operations, and energy conservation.

- *1The "food and food additives" mentioned herein refer to those stipulated in the Food Sanitation Act of Japan.

- *2The FSSC22000 is an international standard on food safety management systems that was developed and is operated by the Foundation for Food Safety Certification (FSSC) and that was approved by the Global Food Safety Initiative (GFSI).

- *3HACCP is a hygiene control method whereby key points for preventing the occurrence of hazards are monitored and recorded continuously in all the processes from the receipt of food ingredients to the manufacture and shipment of products.

- *4An economizer is an ancillary device used for a boiler. It preheats the water to be fed to the boiler by using the exhaust heat from the boiler, thereby improving the efficiency of the boiler.

- *5Condensate is the liquid state of water to which steam has returned due to loss of heat. The temperature of condensate is mostly between 80 and 100 degrees centigrade.

- *KURITIGHT is a registered trademark of Kurita Water Industries Ltd.

Supplementary material: New KURITIGHT Products and Quality Control

New KURITIGHT Products and Quality Control

<Features of the new products>

- 1)KURITIGHT- VR

- This is a boiler water treatment chemical for condensate return systems produced solely from food and food additives, which was the first to be developed in Japan.

- It prevents the corrosion of equipment for steam systems and condensate return systems, such as steam pipes and heat exchangers which use heat.

- 2)KURITIGHT-EF

- This single boiler water treatment chemical serves multiple purposes in a boiler: pH adjustment, prevention of corrosion, deoxidization, prevention of adherence of scale, and sludge dispersion.

- Above all, the scale prevention effect of KURITIGHT-EF is much greater than that of previous products. This enables used steam and condensate to be reclaimed, and the heat and water to be reused for boilers.

- 3)KURITIGHT-AS

- This is a boiler water treatment chemical whose main function is to inhibit the corrosion of economizers used for special circulation boilers.

- It is capable of inhibiting the corrosion of economizers, which would be impossible with our regular chemical treatments, thereby prolonging the service life of economizers and boilers.

<Outline of flows in a boiler plant and new KURITIGHT products>

<Quality control of KURITIGHT>

- 1)Hygiene control with exclusive manufacturing lines

- To prevent the introduction of foreign objects and feedstock for other products, Kurita ensures the comprehensive hygiene control of KURITIGHT products in exclusive manufacturing lines that are separated from those for other products.

- For these products, Kurita uses unused containers (eco-shuttle* containers) with container seals, which enable confirmation as to whether or not they have been opened.

* Eco-shuttle: A Kurita Water Industries' system for collecting returnable containers, under which boiler water treatment chemical containers are collected and reused

- 2)Quality control and traceability

- Kurita checks the quality of raw materials and manufactured products during each of the processes from the receipt of raw materials to the manufacture and shipment of products. Moreover, prior to shipment, Kurita also conducts analyses of the components of products in addition to confirmation of the regular quality standard values. In this way, Kurita ensures comprehensive quality control of the products.

- We plan to allow customers to use the Internet to check the results of pre-shipment inspections and product information (such as the date of manufacture and the location of the manufacturing site) of the KURITIGHT products delivered to them. We also plan to allow customers to view a video introducing the manufacturing lines.